I-crim ebekiweyo ibonakala njengegridi okanye i-lattice. Yenziwe kwiimveliso eziqhubekayo zefilament (imisonto).

Ukuze ugcine imisonto kwindawo efunwayo ye-angle-angle kuyimfuneko ukudibanisa ezi

imisonto kunye. Ngokuchaseneyo neemveliso ezilukiweyo ukulungiswa kwe-warp kunye ne-weft yarns kwi

i-crims ebekiweyo kufuneka yenziwe nge-chemical bonding. Imisonto ye-weft ibekwe ngokulula emazantsi

Oku kuphunyezwa ngenkqubo yokuvelisa.

Ityala elibekiweyouveliswa ngokwamanqanaba amathathu asisiseko:

INYATHELO 1: Amaphepha e-warp asondliwa ukusuka kwimiqadi yecandelo okanye ngokuthe ngqo kwi-creel.

INYATHELO 2: Isixhobo esijikelezayo esikhethekileyo, okanye iturbine, yandlala imisonto enqamlezileyo ngesantya esiphezulu

okanye phakathi kwamaphepha ewaphu. I-scrim ifakwe ngokukhawuleza ngenkqubo yokuncamathelisa ukuqinisekisa ukulungiswa komatshini- kunye nemisonto yendlela enqamlezayo.

INYATHELO LESI-3: I-scrim ekugqibeleni iyomiswa, inyangwe ngokufudumeza kwaye inxeba kwityhubhu

Iinkcazo zee-Scrims eziLayiweyo:

| Ububanzi: | 500 ukuba 2500 mm | Ubude boRolo: | Ukuya kuthi ga kwi-50 000 m | Uhlobo lwemisonto: | Iglasi, ipolyester, ikhabhoni | ||||||||

| Ulwakhiwo: | Isikwere, i-tri-directional | Iipateni: | Ukusuka kwi-0.8 imisonto/cm ukuya kwimitha emi-3/cm | Ukudibanisa: | I-PVOH, i-PVC, i-Acrylic, ilungiselelwe | ||||||||

Iinzuzo zeLaid Scrims:

Ngokubanzicrims wabekazimalunga nama-20 - 40% zibhityile kuneemveliso ezilukiweyo ezenziwe ngomsonto ofanayo kunye nolwakhiwo olufanayo.

Imigangatho emininzi yaseYurophu ifuna uphahla inwebu ubuncinci bokugqunywa kwemathiriyeli kumacala omabini eskrim.Abagxekiukunceda ukuvelisa iimveliso ezibhityileyo ngaphandle kokwamkela amaxabiso aphantsi obugcisa. Kuyenzeka ukuba ugcine ngaphezulu kwe-20 % yezinto ezikrwada ezifana nePVC okanye iPO.

Kuphela zizikrelemnqa ezivumela ukuveliswa kwenwebu ecekethekileyo elinganayo yophahla oluyi-1.2 mm edla ngokusetyenziswa kuMbindi Yurophu. Ilaphu alinakusetyenziselwa ukuphahla i-membrane ezinqabileyo kune-1.5 mm.

Ubume be-awabeka crimayibonakali kancinci kwimveliso yokugqibela kunesakhiwo semathiriyeli elukiweyo. Oku kubangela umphezulu ogudileyo kunye nangaphezulu kwimveliso yokugqibela.

Umphezulu ogudileyo weemveliso zokugqibela eziqulathe ii-laid scrims zivumela ukuwelda okanye ukuncamathelisa iileya zeemveliso zokugqibela ngokulula nangokuzinzileyo kunye nomnye.

Imiphezulu egudileyo iya kuxhathisa umhlaba ixesha elide kwaye ngokuqhubekayo.

Ukusetyenziswa kwei-glassfibre crimi-nonwovens eyomeleziweyo kwi-mits ephezulu yezantya zomatshini wokuvelisa amashiti ophahla lwebhitu-amadoda. Iinyembezi zexesha kunye nomsebenzi onzima kwiplanti yophahla lwebhitumene zinokuthintelwa.

Amaxabiso oomatshini bamashiti ophahla lwebhitumene aphuculwa kancinci ngabadlali.

Izixhobo ezithanda ukukrazuka lula, njengephepha, ifoyile okanye iifilim ezivela kwiiplastiki ezahlukeneyo, ziya kuthintelwa ukuba zingakrazuki ngokufanelekileyo ngokuzilambisa ngezi zinto.crims wabeka.

Ngelixa iimveliso ezilukiweyo zinokubonelelwa nge-loomstate, awabeka crimiyakuhlala ikhulelwa. Ngenxa yale nyaniso sinolwazi olubanzi malunga nokuba sesiphi isibophelelo esinokulungela izicelo ezahlukeneyo. Ukukhetha i-adhesive efanelekileyo kunokwandisa ukudibanisa kwewabeka crimngemveliso yokugqibela kakhulu.

Inyani yokuba i-warp ephezulu nasezantsi ingenacrims wabekaiya kuhlala ikwicala elinye leentambo ezilukiweyo ziqinisekisa ukuba imisonto ye-warp iya kuhlala iphantsi koxinzelelo. Ke ngoko amandla aqinileyo kwicala le-warp aya kuthinjwa kwangoko. Ngenxa yesi siphumo,crims wabekakaninzi kubonisa ukunyusa okuncitshisiweyo kakhulu.Xa i-laminating i-scrim phakathi kweengqimba ezimbini zefilimu okanye ezinye izinto, i-adhesive encinci iya kufuneka kwaye ukudibanisa kwe-laminate kuya kuphuculwa.Ukuveliswa kwe-scrims kuhlala kufuna inkqubo yokomisa i-thermal. Oku kukhokelela ekuncipheni kwangaphambili kwepolyester kunye neminye imisonto ye-thermoplastic eya kuphucula kakhulu unyango olulandelayo olwenziwe ngumthengi.

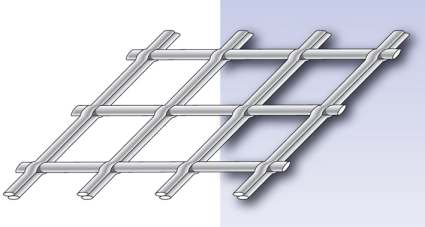

Ulwakhiwo oluqhelekileyo lweLaid Scrims:

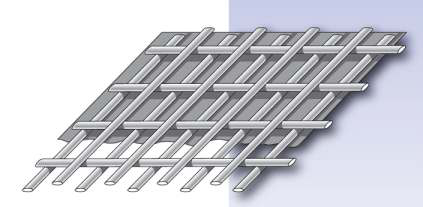

I-wap enye

Olu lolona lwakhiwo lweskrim luxhaphakileyo. Umsonto wokuqala we-warp* phantsi komsonto we-weft** ulandelwa ngumsonto we-warp ngaphezulu komsonto we-weft. Lo mzekelo uphindwa kububanzi bonke. Ngokuqhelekileyo isithuba phakathi kwemisonto siqhelekile kububanzi bonke. Kwisiphambuka imisonto emibini iya kuhlala idibana.

* Warp = yonke imisonto kwicala lomatshini

** weft = yonke imisonto eya kwicala elinqamlezileyo

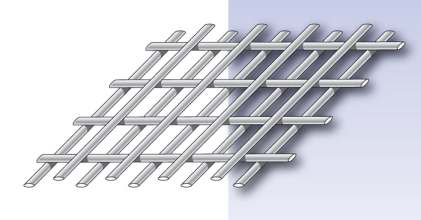

I-wap kabini

Imisonto ye-warp ephezulu nasezantsi iya kuhlala ibekwe enye phezu komnye ukuze imisonto ye-weft ihlale ihleli phakathi komsonto ongasentla nosezantsi. Kwisiphambuka imisonto emithathu iya kuhlala idibana.

Scrim nonwoven laminates

I-scrim (i-warp enye okanye ephindwe kabini) i-laminated kwi-nonwoven (eyenziwe ngeglasi, i-polyester okanye ezinye iifayibha). Kunokwenzeka ukuvelisa i-laminates kunye ne-nonwovens enobunzima ukusuka kwi-0.44 ukuya kwi-5.92 oz./sq.yd.