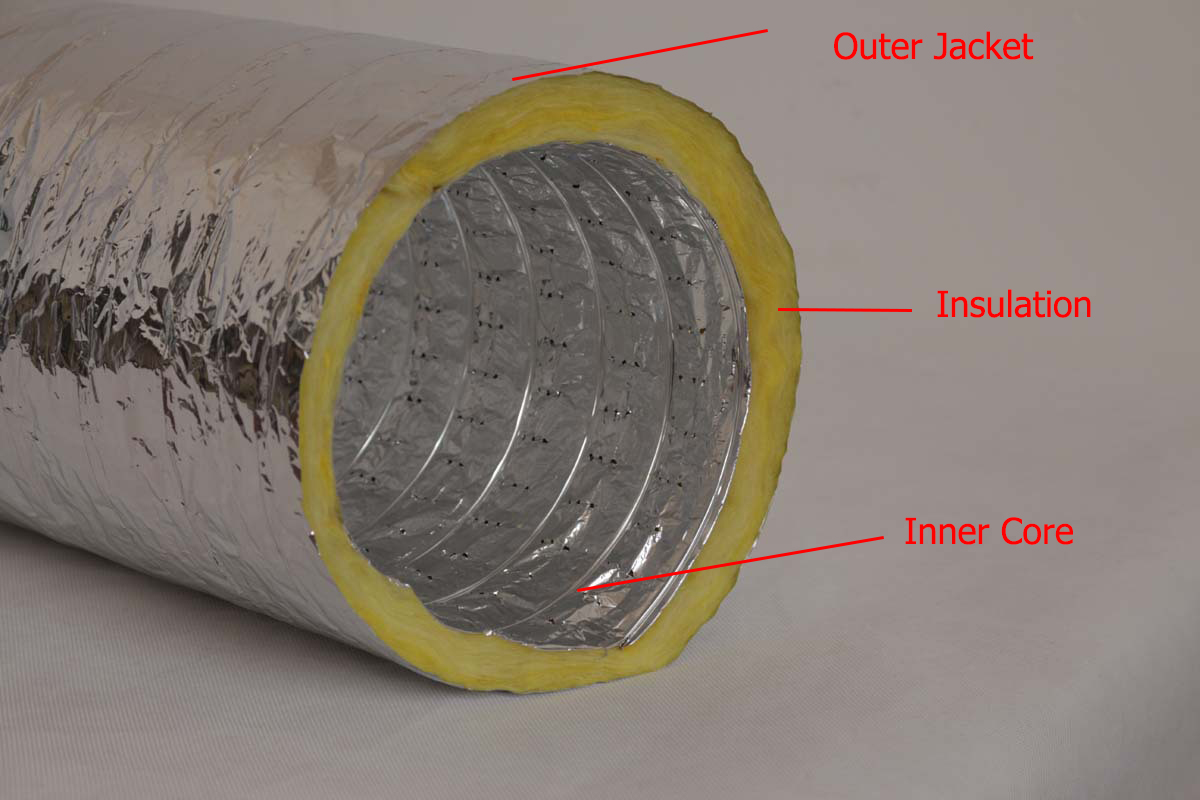

Isembozo se-Fiberglass Pipe Insulation sihloselwe ukuvala ukushisa kwakho kokubili amapayipi esevisi ashisayo nabandayo ukusuka -20°F kuya ku-1000°F. I-insulation yamapayipi ibunjwe kusukela kumafayibha engilazi ahlanganiswe inhlaka eqinile efika ezigabeni ezinamahinga angamamitha angu-3 ubude. I-fiberglass isongwe nge-All-Service Jacketing emhlophe enethango elizivalayo ukuze lifakwe ngokushesha nangokuvikelekile. Ingxenye ngayinye eyizinyawo ezi-3 yokufakwa kwamapayipi okuhweba iza netheyiphu ye-butt-strip esetshenziselwa ukuxhuma izingxenye ezimbili zokufakwa kwamapayipi ndawonye.

I-Fiberglass Pipe Insulation kanye ne-Mineral Wool Pipe Insulation yizinhlobo ezimbili zokuvala amapayipi eseli avulekile. Emzamweni wokugcina lokhu okuthunyelwe kungezona ezesayensi futhi kulula ukukuqonda, imikhiqizo yokuvala amapayipi eseli avaliwe ayivumeli amanzi ukuthi adlule kuwo kuyilapho imikhiqizo yokufakwa kwamapayipi eseli evulekile, ngokuvamile kuvame ukugqunywa kwamapayipi e-fiberglass, ivumela amanzi ukuba adlule emiculweni yawo.

Ukumuncwa komsindo kulula ukukulawula. Iningi lemikhiqizo yokufaka i-batt kanye ne-board insulation ishicilele i-coefficient yokumunca umsindo (NRC) eshidini labo ledatha.

Ukuphakama kwe-Sound Absorption Coefficient kuba ngcono kuma-acoustics ngaphakathi kwegumbi lakho.

Ukuvikela umsindo kuba nzima kakhulu esixazululweni esifanele senkinga yakho. Uma siyibheka ngokwedlulele, ake sicabangele udonga lukakhonkolo oluqhathaniswa nodonga olwakhiwe kuphela i-fiberglass batt yokukhanya okukhanyayo (ayikho i-drywall nhlobo). Uma usegunjini eliseduze ngemuva kodonga lukakhonkolo uzozwa izingxoxo zomakhelwane wakho kancane kakhulu kunalapho bekunebhethi ye-fiberglass kuphela phakathi kwakho nomakhelwane wakho. Kulesi sibonelo, ukhonkolo uyinto ephakeme kakhulu yokuvikela umsindo kune-fiberglass batt insulation kuphela. Uma ubungaphakathi kwegumbi unengxoxo, nokho-ke, uzozwa i-echo encane kakhulu uma udonga lwakho luyi-fiberglass batt uma luqhathaniswa nodonga lukakhonkolo. Kulesi sibonelo, i-fiberglass batt iwumunca umsindo ongcono kakhulu kunodonga lukakhonkolo.

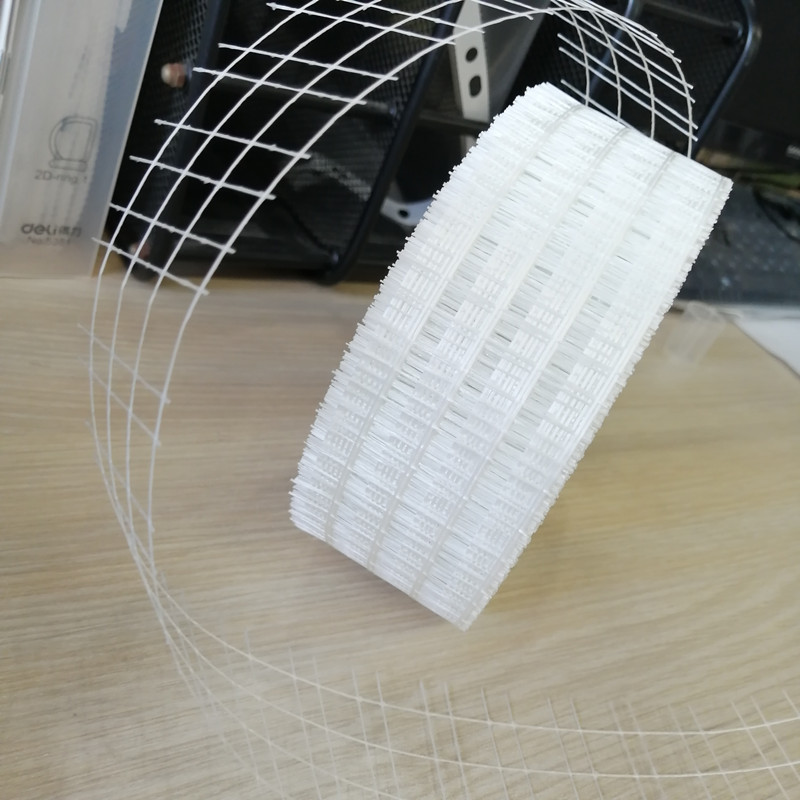

Ama-scrim ajwayelekile acishe abe ngu-20 - 40 % azacile kunemikhiqizo elukiwe eyenziwe ngentambo efanayo futhi enokwakheka okufanayo.

Izindinganiso eziningi zaseYurophu zidinga ulwelwesi lokufulela ukumbozwa kwempahla ezinhlangothini zombili ze-scrim. Izigebengu ezibekiwe zisiza ukukhiqiza imikhiqizo emincane ngaphandle kokwamukela amanani ezobuchwepheshe anciphile. Kungenzeka ukonga ngaphezu kwama-20 % wezinto ezingavuthiwe ezifana ne-PVC noma i-PO.

Izigebengu kuphela ezivumela ukukhiqizwa kolwelwesi oluncane lokufulela ngezingqimba ezintathu (1.2 mm) oluvame ukusetshenziswa e-Central Europe. Izindwangu azikwazi ukusetshenziselwa ulwelwesi lokufulela oluncane kuno-1.5 mm.

Isakhiwo se-scrim esibekiwe sibonakala kancane emkhiqizweni wokugcina kunokwakheka kwezinto ezilukiweyo. Lokhu kubangela ukuthi umkhiqizo wokugcina ube bushelelezi futhi ulingane.

Ingaphezulu elibushelelezi lemikhiqizo yokugcina equkethe ama-laid scrims livumela ukushisela noma ukunamathisela izingqimba zemikhiqizo yokugcina kalula nangokuqinile komunye nomunye.

Izindawo ezibushelelezi zizomelana nokungcoliswa isikhathi eside nangokuphikelela.

Ukusetshenziswa kwe-glassfibre scrim kuqinise ama-nonwovens per-mits isivinini esiphezulu somshini wokukhiqiza amashidi ophahla lwe-bitu-amadoda. Ngakho-ke kungavinjelwa izinyembezi ezicindezela isikhathi nomsebenzi esitshalweni se-bitumen roof sheet.

Amanani emishini yamashidi ophahla lwebitumen athuthukiswa kancane kancane yizigebengu.

Izinto ezivame ukuklebhuka kalula, njengephepha, i-foil noma amafilimu avela kumapulasitiki ahlukene, zizovinjelwa ukuthi zingadabuki kahle ngokuzigcoba ngama-scrims abekiwe.

Nakuba imikhiqizo elukiwe ingase ihlinzekwe nge-loomstate, i-scrim ebekiwe iyohlale ikhulelwe. Ngenxa yaleli qiniso sinolwazi olubanzi mayelana nokuthi isiphi isibophezelo esingalungela kangcono izinhlelo zokusebenza ezahlukene. Ukukhethwa kwe-adhesive efanele kungase kuthuthukise ukuhlangana kwe-scrim ebekiwe nomkhiqizo wokugcina kakhulu.

Iqiniso lokuthi i-warp ephezulu nephansi kuma-scrims amisiwe iyohlale ihlangothini olufanayo lwezintambo ezisontekile iqinisekisa ukuthi imicu eqondile iyohlale icindezelekile. Ngakho-ke amandla aqinile ekuqondeni kwe-warp azothathwa ngokushesha. Ngenxa yalokhu mphumela, ama-scrims abekiwe ngokuvamile abonisa ubude obuncishisiwe kakhulu.Lapho i-laminating i-scrim phakathi kwezingqimba ezimbili zefilimu noma ezinye izinto, ukunamathela okuncane kuzodingeka futhi ukuhlangana kwe-laminate kuzothuthukiswa.Ukukhiqizwa kwama-scrims kudinga njalo inqubo yokomisa okushisayo. Lokhu kuholela ekuncipheni kwe-polyester nezinye izintambo ze-thermoplastic okuzokwenza ngcono kakhulu ukwelashwa okulandelayo okwenziwa yikhasimende.

Isikhathi sokuthumela: Jan-07-2022