I-scrim ebekiwe ibukeka njengegridi noma i-lattice. Yenziwe ngemikhiqizo ye-filament eqhubekayo (imicu).

Ukuze ugcine izintambo zisesimweni esifiselekayo se-engeli kwesokudla kuyadingeka ukujoyina lezi

izintambo ndawonye. Ngokuphambene nemikhiqizo elukiweyo ukulungiswa kwe-warp ne-weft yarns in

izigebengu ezibekiwe kumele zenziwe nge-chemical bonding. imicu ye-weft imane ibekwe ngaphesheya

Lokhu kufezwa ngenqubo yokukhiqiza.

I-scrim ebekiwekukhiqizwa ngezinyathelo ezintathu eziyisisekelo:

ISINYATHELO 1: Amashidi entambo ye-warp aphakelwa kusuka emishayweni yesigaba noma ngokuqondile ku-creel.

ISINYATHELO 2: Idivayisi ekhethekile ezungezisayo, noma i-turbine, ibeka izintambo eziphambanayo ngesivinini esikhulu

noma phakathi kwama-wap sheet. I-scrim ifakwa ngokushesha ngesistimu yokunamathela ukuze kuqinisekiswe ukulungiswa komshini- kanye nezintambo eziqondisayo.

ISINYATHELO SESI-3: I-scrim ekugcineni iyomiswa, ilashwe ngokushisa futhi ilinyazwe ngeshubhu

Imininingwane ye-Laid Scrims yethu:

| Ububanzi: | 500 ukuze 2500 mm | Ubude bokugoqa: | Kufika ku-50 000 m | Uhlobo Lwezintambo: | Ingilazi, i-polyester, ikhabhoni | ||||||||

| Ukwakha: | Isikwele, i-tri-directional | Amaphethini: | Ukusuka ku-0.8 kuya ku-3 cm / cm | I-Bonding: | I-PVOH, i-PVC, i-Acrylic, eyenziwe ngokwezifiso | ||||||||

Izinzuzo zeI-Laid Scrims:

Ngokuvamilewabeka izigebengucishe izacile ngo-20 - 40% kunemikhiqizo elukiwe eyenziwe ngentambo efanayo futhi inokwakhiwa okufanayo.

Izindinganiso eziningi zaseYurophu zidinga ulwelwesi lokufulela ukumbozwa kwempahla ezinhlangothini zombili ze-scrim.Izigebengu ezibekiweukusiza ukukhiqiza imikhiqizo emincane ngaphandle kokwamukela amanani ezobuchwepheshe anciphile. Kungenzeka ukonga ngaphezu kwama-20 % wezinto ezingavuthiwe ezifana ne-PVC noma i-PO.

Izigebengu kuphela ezivumela ukukhiqizwa kolwelwesi oluncane lokufulela ngezingqimba ezintathu (1.2 mm) oluvame ukusetshenziswa e-Central Europe. Izindwangu azikwazi ukusetshenziselwa ulwelwesi lokufulela oluncane kuno-1.5 mm.

Isakhiwo se-awabeka isihlukuayibonakali kangako emkhiqizweni wokugcina kunesakhiwo sezinto ezilukiweyo. Lokhu kubangela ukuthi umkhiqizo wokugcina ube bushelelezi futhi ulingane.

Ingaphezulu elibushelelezi lemikhiqizo yokugcina equkethe ama-laid scrims ivumela ukushisela noma ukunamathisela izingqimba zemikhiqizo yokugcina kalula nangokuqinile enye nenye.

Izindawo ezibushelelezi zizomelana nokungcoliswa isikhathi eside nangokuphikelela.

Ukusetshenziswa kwei-glassfibre scrimama-nonwovens aqinisiwe ama-per-mits aphezulu ngesivinini somshini wokukhiqiza amashidi ophahla lwe-bitu-amadoda. Ngakho-ke kungavinjelwa izinyembezi ezicindezela isikhathi nomsebenzi esitshalweni se-bitumen roof sheet.

Amanani emishini yamashidi ophahla lwebitumen athuthukiswa kancane kancane yizigebengu.

Izinto ezivame ukudabuka kalula, njengephepha, i-foil noma amafilimu avela kumapulasitiki ahlukene, zizovinjelwa ukuthi zingadabuki ngokuphumelelayo ngokuwalalisawabeka izigebengu.

Nakuba imikhiqizo elukiwe ingase ihlinzekwe nge-loomstate, awabeka isihlukuiyohlala ikhulelwe. Ngenxa yaleli qiniso sinolwazi olubanzi mayelana nokuthi isiphi isibophezelo esingalungela kangcono izinhlelo zokusebenza ezahlukene. Ukukhethwa kwe-adhesive efanele kungase kuthuthukise ukubopha kwe-wabeka isihlukungomkhiqizo wokugcina kakhulu.

Iqiniso lokuthi i-warp ephezulu nephansiwabeka izigebenguiyohlala ihlezi ohlangothini olulodwa lwezintambo ezisontekile iqinisekisa ukuthi imicu eqondile iyohlale ingaphansi kokucindezeleka. Ngakho-ke amandla aqinile ekuqondeni kwe-warp azothathwa ngokushesha. Ngenxa yalo mphumela,wabeka izigebengungokuvamile ubonisa ubude obuncishisiwe kakhulu.Lapho i-laminating i-scrim phakathi kwezingqimba ezimbili zefilimu noma ezinye izinto, ukunamathela okuncane kuzodingeka futhi ukuhlangana kwe-laminate kuzothuthukiswa.Ukukhiqizwa kwama-scrims kudinga njalo inqubo yokomisa okushisayo. Lokhu kuholela ekuncipheni kwe-polyester nezinye izintambo ze-thermoplastic okuzokwenza ngcono kakhulu ukwelashwa okulandelayo okwenziwa yikhasimende.

Izakhiwo ezijwayelekile zeI-Laid Scrims:

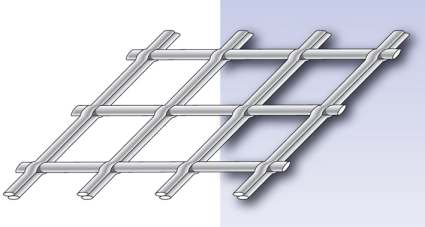

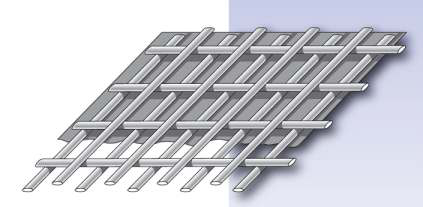

I-wap eyodwa

Lona ukwakhiwa kwe-scrim okuvame kakhulu. Intambo ye-warp* yokuqala ngaphansi kwentambo ye-weft** ilandelwa intambo ye-warp ngaphezu kwentambo ye-weft. Le phethini iphindaphindiwe kubo bonke ububanzi. Ngokujwayelekile isikhala phakathi kwemicu sivamile kubo bonke ububanzi. Ezimpambanweni zomgwaqo imicu emibili iyohlala ihlangana.

* i-warp = yonke imicu ekuqondeni komshini

** i-weft = yonke imicu ephambanayo

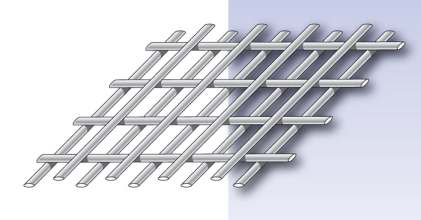

I-wap kabili

Izintambo ezigoqekayo ezingenhla nezingezansi ziyohlale zibekwe eyodwa phezu komunye ukuze imicu ye-weft ihlale iqinile phakathi kwentambo evukile engenhla nengaphansi. Ezimpambanweni zomgwaqo kuzohlale kuhlangana imicu emithathu.

Gcoba ama-laminates angalukiwe

I-scrim (i-warp eyodwa noma ephindwe kabili) i-laminated phezu kwe-nonwoven (eyenziwe ngengilazi, i-polyester noma eminye imicu). Kungenzeka ukukhiqiza ama-laminates anama-nonwovens anesisindo esisuka ku-0.44 kuya ku-5.92 oz./sq.yd.