Francis Ford Coppola’s latest venture into indie-land also extends his late-career journey into his own head, though Twixt is more overtly entertaining than Youth Without Youth or Tetro (if still not quite sharp enough to be wholly satisfying). Val Kilmer stars as a horror writer who stops off in a creepy small town on a book tour, and discovers a murder-mystery that involves Edgar Allan Poe, a creepy preacher, a hotel full of dead girls, a grizzled sheriff, and a group of teenagers heavily into the occult. Kilmer sticks around, looking for inspiration for a book (and for the hefty advance such an idea could bring him). But as he works into the night, getting increasingly hammered, he has strange visions that relate both to the case and to a tragic incident from his past. Meanwhile, Coppola revisits his days making gothic horror and B-movies. (Twixt is in 3D, but only for two scenes, for which the audience is cued with a William Castle-like “put on your glasses now” effect.) He riffs too on the difficulties of the creative process, by forcing himself to look back at the real-life accidental death of his son Gian-Carlo, 25 years ago. On the whole, the film is a curious trip down memory lane, anchored by a weird performance by a chubby Kilmer. It’s never dull—and it’s occasionally funny—but as with the films that immediately preceded it, Twixt is strangely lacking in command. It’s Coppola trying things out: a split-screen here, a Lynchian interlude there. He’s working from his gut, but not quite enough from his head.

From washrooms to factory floors, Fibematics’ products are helping to replace traditional textile towels, rags and wipers worldwide.

Sony Electronics has joined as a member of a growing number of e-Stewards Enterprise companies. These corporations and institutions are committed to using the most globally responsible recycling companies that are certified to the e-Stewards standard. The e-Stewards standard disallows exporting hazardous electronic waste to developing countries and employs the most rigorous criteria to prevent data breaches from discarded hardware. Besides being a leading manufacturer of consumer electronic products, Sony Electronics is committed to designing with the environment in mind and helping to eliminate externalities throughout the supply and disposal chains. Beyond its efforts with regards to recycling, Sony’s vision is to aim for a zero environmental footprint by 2050 to conserve resources and curb climate change.

Sigmatex UK (Runcorn, U.K.) introduced sigmaST, a spread-tow fabric available in 50g/1.76 oz and 75g/2.65 oz per ply areal weights, with a heavier 100g/3.53 oz per ply version also in development. The spread tape width is 16 mm/0.63 inch, and fabrics are woven with a new “state-of-the-art, high-output production process” to form a near-zero-crimp fabric. Narrower tapes are in development, says Andrew Ball, lead development engineer for multiaxial fabrics at Sigmatex. The company also showcased sigmaRF, a recycled/reclaimed carbon fiber noncrimp multiaxial (±45°) flexible fabric woven from 55-mm/2.2-inch recycled carbon staple fibers blended with a thermoplastic fiber. The fabric contains about 48 percent carbon by volume. It has significantly lower environmental impact than virgin carbon fiber-based materials. The fabric is targeted to the automotive market, primarily for nonstructural parts made with standard thermoplastic processes, where the surface finish isn’t an issue. (See Fig. 6.)

Solar Impulse 2 (Si2) was designed with TPT materials in mind by Solar Impulse in conjunction with its airframe manufacturer, Decision SA — a member, with Multiplast SAS (Vannes, France), of Groupe Carboman SA (Ecublens, Switzerland). Decision constructed the Si2 airframe in its Ecublens facility.

that is, a customer-selected newer-model Corvette that will be stripped and rebuilt. The donor is placed on a cart, which enables easy transport throughout the shop and raises the car to a more ergonomic working height. Currently, customers can choose to use a C5 (production years from 1995 to 2004) or a C6 (2005 to 2013) Corvette convertible as the donor.

“We’ve made hundreds of molds using wet layup,” says Waimer, “but we chose to infuse all of the molds for this project because we wanted to pursue a very high-end production from the beginning.” He adds, “We wanted to ensure fewer voids and better saturation in the molds, so that the composite hulls and decks we made from these would be of the highest quality.” Waimer notes this also helps to maintain dimensional stability of the final parts.

Prior to painting, however, each car is moved into the fitting room, our next stop, where all CFRP panels are precision measured. Here, chrome trim and bumpers are fitted to each car to ensure proper alignment after the final clearcoat. “Even a misalignment of a few thousandths of an inch will require putty work and blocking to get exact precision,” says Graf. Custom gages are used to check gaps and alignment. Parts are then removed for painting.

Johnston says he doesn’t think the “Star Wars” original trilogy effects crew should be remembered as a well-oiled machine or a crack team with a clear road to success. They were something less than that, and also more.

In her first time showing at her home city’s design week, Lara Bohinc presented new furniture at Matter of Stuff Gallery, as well as a more unexpected venture: Colorful lacquered boxes, shown at Gallery Fumi. The pieces are the result of a two-week residency the designer did with Japanese masters in the rare art of Urushi. "They make these boxes with wood from the cinnamon tree," Bohinc explains. Then they cover it in thin layers of cotton fabric and paint on layer after layer of lacquer—up to 30 layers." After becoming fascinated with these artisans during her visit, Bohinc designed versions of the box in geometric, colorful forms more in line with her own style, then enlisted the masters to make them. Gallery Fumi, 2 Hay Hill, Mayfair.

The selling point of 3Di, well championed after so many years in use, is the strength and stretch resistance in the sail without the parasitic weight of a laminate (as it was with 3DL). Strength and modulus are all baked into the tapes, which are then oriented by the tape heads such that there’s the right amount of material in the high-load parts of the sail and less where it doesn’t need to be. Durability is the North salesman’s other 3Di guarantee, as well. With 3Di Endurance, a protective scrim is added for a 10-percent weight gain. Customers don’t order the same surface protection with 3Di RAW, which is less of an issue for grand-prix teams with sail inventory turnover.

"Think of Fibematics the next time you’re at a barbecue restaurant and use a wet wipe to clean up that messy sauce," Bloovman jokes. "The wipe material may have come from our factory!"

At the AT-AT’s birth: the improvising of a ‘Star Wars’ icon | Chinese Non-Woven Scrims Related Video:

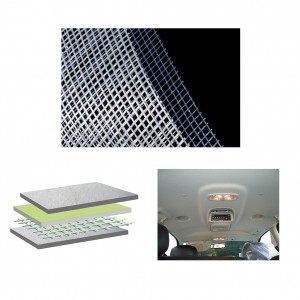

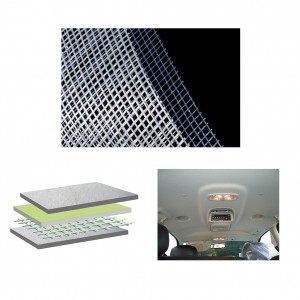

We are also focusing on enhancing the things administration and QC program in order that we could keep fantastic advantage within the fiercely-competitive enterprise for Carbon Laminatedscrims Fabric For Automotive , Fiberglass Non-Woven Laid Scrims For Automotive , Reinforcement Laid Scrims Mesh Fabric , "Good quality and reasonable price" are our business principles. If you are interested in our products or have any questions, please feel free to contact us. We hope to establish cooperative relationships with you in the near future.