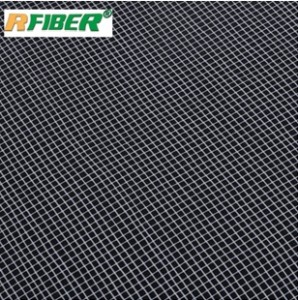

Fiberglass mesh

It is two warp thread leno and one weft thread, woven by rapier loom first, and then coated with the glue.

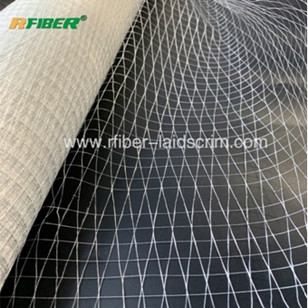

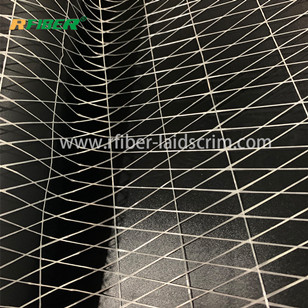

Laid-scrim

The laid scrim is produced in three basic steps:

Step 1: warp yarn sheets are fed from section beams of directly from a creel.

Step 2: a special rotating device, or turbine, lays cross yarns at high speed on or between the warp sheets. The scrim is immediately impregnated with an adhesive system to ensure the fixation of machine and cross direction yarns.

Step 3: the scrim is finally being dried, thermally treated and wound on a tube by a separate device.

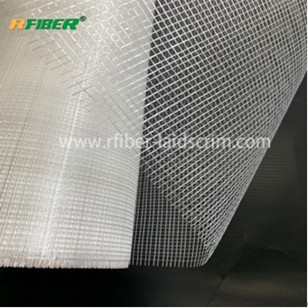

Laid scrim is very light, the minimum weight can be 3-4 grams only, this saves the large percent of raw material, and heavy can be about 100 grams.

Weft yarn and warp yarn laying onto each other, the joint thickness is nearly the same as the yarn thickness itself. The thickness of the whole structure is very even and very thin.

Because the structure is bonded by the adhesive, the size is fixed, it keeps the shape.

Many sizes are available for the laid scrims, such as 3*3, 5*5, 10*10, 12.5*12.5, 4*6, 2.5*5, 2.5*10 etc.

Application:

Building

Laid scrim is widely applied in a aluminum foil industry. It can help manufacture to develop the production efficiency as the roll length can reach 10000m. It also makes the finished product with better appearance.

GRP pipe fabrication

Double yarn non woven laid scrim is an ideal choice for pipe maufacturers. The pipeline with laid scrim has good uniformity and expansibility, cold resistance, high temperature resistance and crack resistance, which can greatly extend the service life of the pipeline.

Packaging

Laid scrim mainly used for producing Foam tape composite, Double sided tape compound & Lamination of masking tape. Envelopes, Cardboard containers, Transport boxes, Anticorrosive paper, Air bubble cushioning, Paper bags with windows, high transparent films can us also.

Flooring

Now all major domestic and foreign manufactures are applying laid scrim as the reinforcement layer to avoiding the joint or bulge between pieces, which is caused by the heat expansion and contraction of materials.

Other usages: PVC flooring/PVC, Carpet, Carpet tiles, Ceramic, wood or glass mosaic tiles, Mosaic parquet(underside bonding), Indoor and outdoor, tracks for sports and playgrounds.

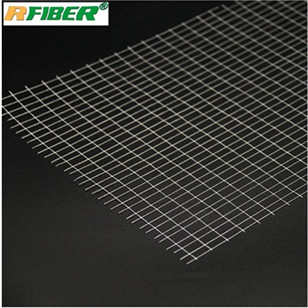

Laid scrim is cost-effective! Highly automatic machinery production, low raw material consumption, less labor input. Compare to traditional mesh, laid scrims have a great advantage in price!

Welcome to visit Shanghai Ruifiber, offices and work plants, at your earliest convenience.——www.rfiber-laidscrim.com

Post time: Jul-09-2021