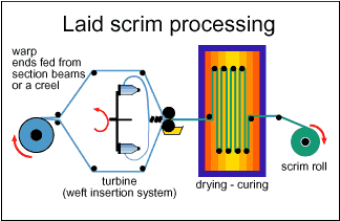

Description of the process

The laid scrim is produced in three basic steps:

-

STEP 1: Warp yarn sheets are fed from section beams or directly from a creel.

-

STEP 2: A special rotating device, or turbine, lays cross yarns at high speed on or between the warp sheets. The scrim is immediately impregnated with an adhesive system to ensure the fixation of machine- and cross direction yarns.

-

STEP 3: The scrim is finally being dried, thermally treated and wound on a tube by a separate device.

Double sided tapes allow you to bond two surfaces together quickly and easily, giving you a high quality, reliable and permanent bond.

These high performance tapes offer you economical and effective bonding solutions whilst still providing the capabilities to meet the most challenging applications.

Double Sided Tape Applications Include

- Foam, felt and fabric lamination

- Automotive interior, low VOC’s

- Sign, banners and display

- Nameplates, badge and emblem fixing

- EPDM profiles and extrusions

- Print and graphic applications

- Double sided adhesive tape for mirrors

- High Performance Packaging Tape Solutions

What is Foam Tape?

- Foam tape comprise of a open/closed cell foam base such as: Polyethylene (PE) ,polyurethane (PU) and PET, coated with high performance acrylic or rubber adhesive, it is very suitable for sealing and permanent bonding.

- Features of foam tape

- • Strong tensile strength and bonding force

- • Good abrasion, corrosion and moisture resistance

- • Can be used in various environments

- • Good mechanical property, easy to die cut and laminating

- • Various thickness for different applications

- • Good temperature resistance can be applied in ultra cold area

- Applications for foam tape?

- Double-sided foam tapes are widely used for temporary or permanent fastening, sealing, packaging, sound dampening, thermal insulation, and gap filling. Foam tapes come in a variety of thicknesses, and easy to die cut.

Applications

- Bonding

- Insulation

- Mounting

- Protection

- Sealing

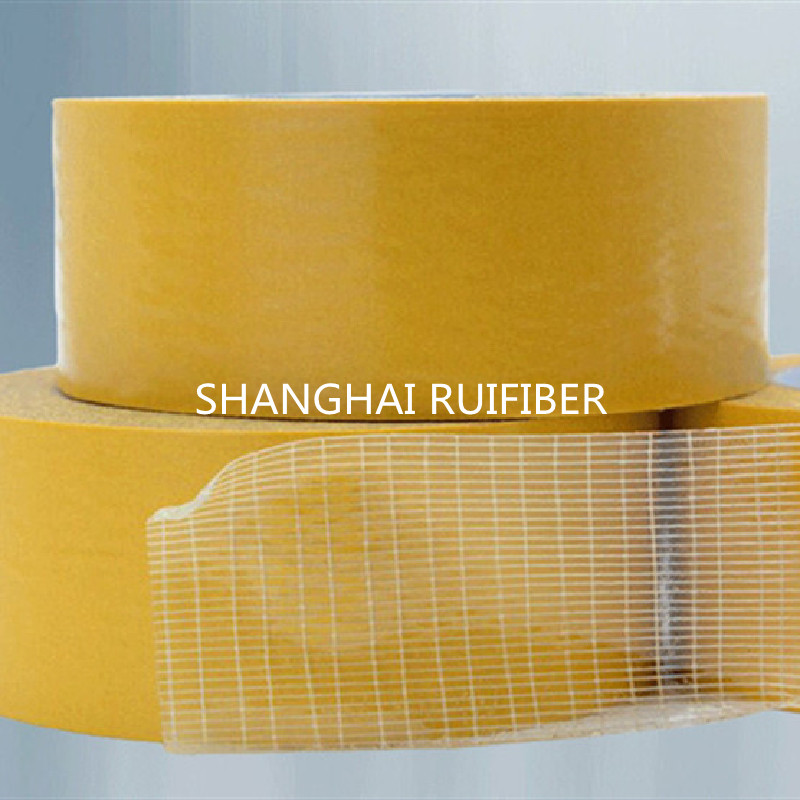

Adhesive films with scrim increase only insignificantly in thickness due to the embedded polyester threads and like liner less transfer tapes, are suitable for applications requiring low thickness.

However, they offer some advantages: Due to the scrim reinforcement they are more stable and can be further processed more easily, e.g. to cut rolls. The stabilized adhesive film also simplifies manual and machine processing of the adhesive tape.

Scrim tapes are suitable for wide, large-area bonding as well as for narrow applications such as the bonding of baseboards or various plastic profiles. Despite the scrim intermediate carrier, the product structure remains cost-effective.

Product features:

High tack hot melt adhesive

Especially high initial and final adhesion

Thin adhesive film, stabilized by polyester scrim

Easy to install, silicone-coated release liner made of paper

Suitable for various, also low-energy materials

Various log roll and cut roll formats available

Various combination of yarns, binder, mesh sizes, all is available. Please feel free to let us know if you have any more requirements. It’s our great pleasure to be your services.

Ruifiber designs, manufactures and distributes materials and solutions which are key ingredients in the wellbeing of each of us and the future of all. They can be found everywhere in our living places and our daily life: in buildings, transportation, infrastructure and in many industrial applications. They provide comfort, performance and safety while addressing the challenges of sustainable construction, resource efficiency and climate change.

Post time: Nov-05-2021