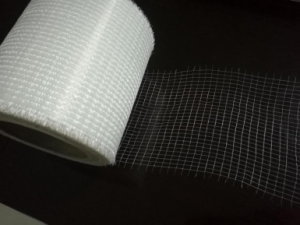

A laid scrim looks like a grid or lattice. It is made from continuous filament products (yarns).

In order to keep the yarns in the desired right-angled position it is necessary to join these yarns together. In contrast to woven products the fixation of the warp and weft yarns in laid scrims must be done by chemical bonding. Weft yarns are simply laid across a bottom warp sheet, then trapped with a top warp sheet. The whole structure is then coated with an adhesive to bond the warp and weft sheets together creating a robust construction.

This is achieved through a manufacturing process.

Applications

Laid scrims is the best material for laminating with many other kinds of materials, due to its light weight, high strength, low shrinkage/elongation, corrosion preventive, it offers tremendous value

compared to conventional material concepts. This makes it has an extensive fields of applications.

Warp Tensile: 80-85N/50mm

Weft Tensile: 45-70N/50mm

Material Weight: 7-10g/m2

Welcome to visit our office and work plants!

Post time: Sep-25-2020