The laid scrim is produced in three basic steps:

Step 1: warp yarn sheets are fed from section beams or directly from a creel.

Step 2: a special rotating device, or turbine, lays cross yarns at high speed on or between the warp sheets. The scrim is immediately impregnated with an adhesive system to ensure the fixation of machine and cross direction yarns.

Step 3: the scrim is finally being dried, thermally treated and wound on a tube by a separate device.

The difference of laid scrims and woven scrims

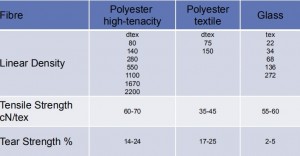

Laid scrims are suitable for thinner products, lower production costs, suitable for gentle finishing processes, for big quantities, low warp elongation

woven scrims are suitable for thicker products, economical also for smaller quantities, suitable also for physically stressing finishing processes, even surface for membrane products

Laid scrims is the best material for laminating with many other kinds of materials, due to its light weight, high strength, low shrinkage/elongation, corrosion preventive, it offers tremendous value compared to conventional material concepts. This makes it has an extensive fields of applications.

Laid scrims application:

Building, Automotive, Packaging, Non-wovens, Outdoor&sport, Electrical, Medical, Construction, pipe making, GRP fabrication etc.

Supplying countries: China, UK, Malaysia, Russia, Saudi Arabia, Bahrain, Turkey, India etc.

Welcome to visit Ruifiber head office and factories!

Post time: Jun-12-2020