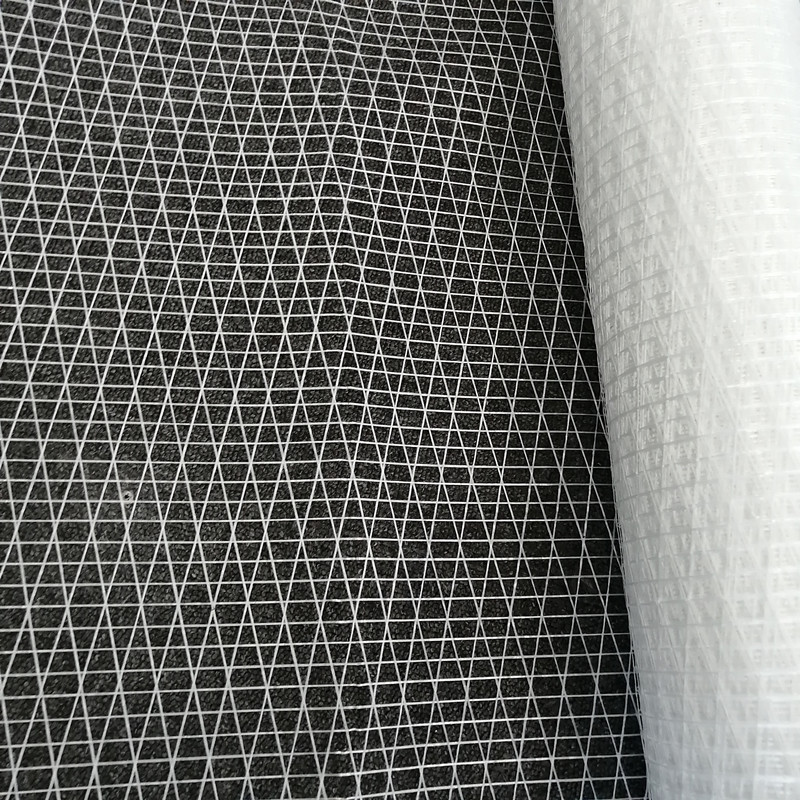

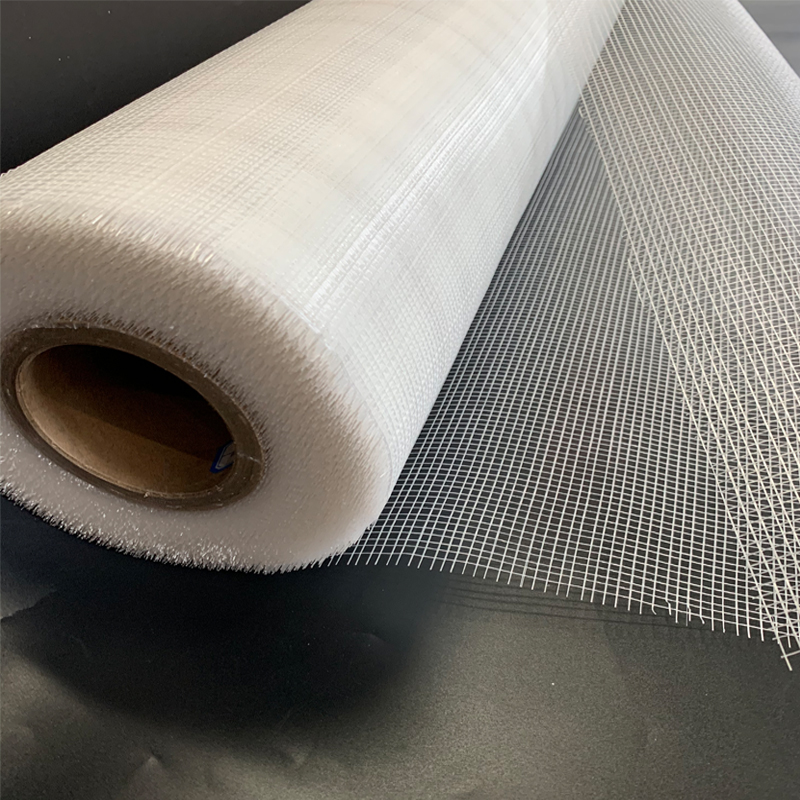

A laid scrim looks like a grid or lattice. It is a cost-effective reinforcing fabric made from continuous filament yarn in an open mesh construction. The laid scrim manufacturing process chemically bonds non-woven yarns together, enhancing the scrim with unique characteristics.

High tenacity, Flexible, Tensile strength, Low shrinkage, Low elongation, Fire-proof Flame retardant,Waterproof,Corrosionresistant,Heat-sealable,Self-adhesive,Epoxy-resin friendly, Decomposable, Recyclable etc.

Industrial tarpaulin shade is used in the industries for protecting the industrial raw-materials and finished goods of the industries from weather & moisture to protect them from rust & corrosion. They also aid in carrying our industrial work process by shading the workshops.

A tarpaulin or tarp is a large sheet of strong, flexible, water-resistant or waterproof material, often cloth such as canvas or polyester coated with polyurethane, or made of plastics such as polythylene. Tarpaulins often have reinforced grommets at the corners and along the sides to form attachment points for rope, allowing them to be tied down or suspended.

Inexpensive modern tarpaulins are made from woven polyethylene; this material is so associated with tarpaulins that it has become colloquially known in some quarters as polytarp.

Tarpaulins are used in many ways to protect persons and things from wind, rain, and sunlight. They are used during construction or after disasters to protect partially built or damaged structures, to prevent mess during painting and similar activities, and to contain and collect debris. They are used to protect the loads of open trucks and wagons, to keep wood piles dry, and for shelters such as tents or other temporary structures.

A perforated tarpaulin

Tarpaulins are also used for advertisement printing, most notably for billboards. Perforated tarpaulins are typically used for medium to large advertising, or for protection on scaffoldings; the aim of the perforations (from 20% to 70%) is to reduce wind vulnerability.

Polyethylene tarpaulins have also proven to be a popular source when an inexpensive, water-resistant fabric is needed. Many amateur builders of plywood sailboats turn to polyethylene tarpaulins for making their sails, as it is inexpensive and easily worked. With the proper type of adhesive tape, it is possible to make a serviceable sail for a small boat with no sewing.

Plastic tarps are sometimes used as a building material in communities of indigenous North Americans. Tipis made with tarps are known as tarpees.

A polythylene tarpaulin (“polytarp”) is not a traditional fabric, but rather, a laminate of woven and sheet material. The center is loosely woven from strips of polyethylene plastic, with sheets of the same material bonded to the surface. This creates a fabric-like material that resists stretching well in all directions and is waterproof. Sheets can be either of low density polyethylene (LDPE) or high density polyethylene (HDPE). When treated against ultraviolet light, these tarpaulins can last for years exposed to the elements, but non-UV treated material will quickly become brittle and lose strength and water resistance if exposed to sunlight.

We are always looking for new development partners who wish to explore our product range and create something new together. Our scrims can find their use in a number of applications.Welcome to visit Shanghai Ruifiber, offices and work plants, at your earliest convenience.——www.rfiber-laidscrim.com

Post time: Oct-29-2021