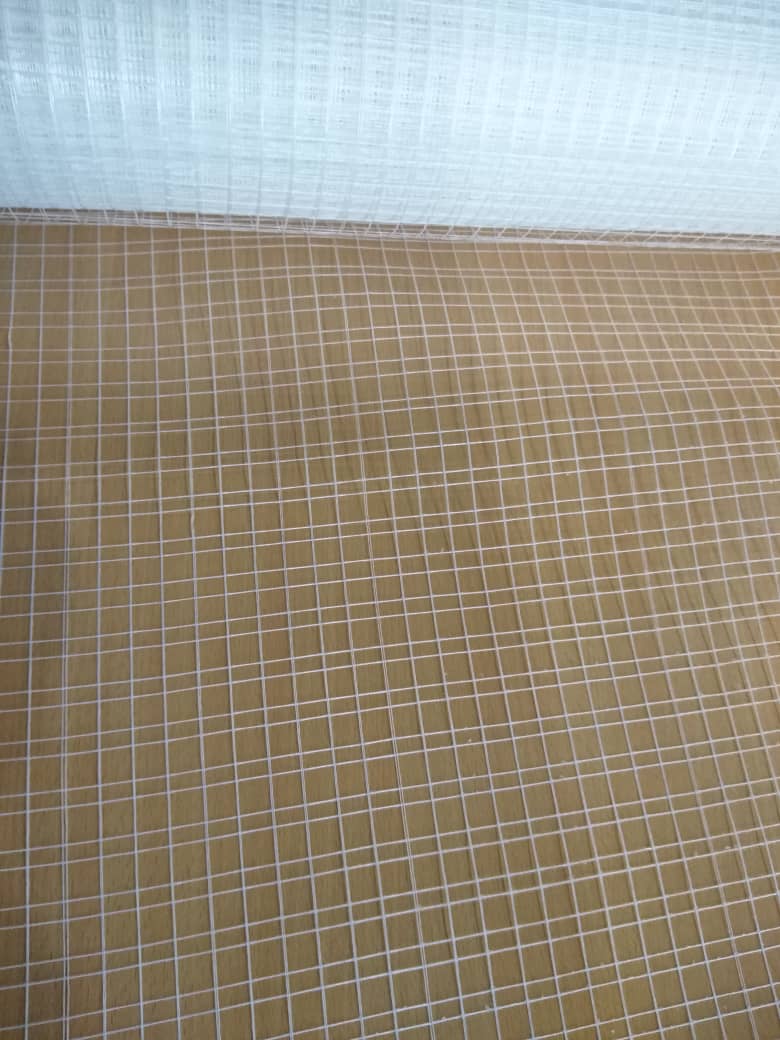

ibeka i-scrim ijongeka ngathi yigridi okanye i-lattice. Yenziwe kwiimveliso zefiliment eziqhubekayo (iintambo). Ukuze ugcine iintambo kwindawo enqwenelekayo ye-engled ifuneka kunyanzelekile ukuba ujoyine. Ngokwahlukileyo kwi-Wolking hlasela ukulungiswa kwe-warp kunye neentambo ze-weftn kwi-scrims kufuneka kwenziwe ngokubekwa ngumchiza. Imisonto ye-Weft ilele nje ezantsi oku kufezekiswa ngenkqubo yokwenziwa.

Ngokubanzi i-scrims inama-20 - 40% incinanana kunemveliso elukiweyo eyenziwe ukusuka kwindawo enye kunye nolwakhiwo olufanayo.

Imigangatho emininzi yaseYurophu ifuna ukuba uphahla lube ne-membrane enobuncinci kumacala omabini e-skrim. I-scrims incedisa ukuvelisa iimveliso ezincinci ngaphandle kokwamkela amaxabiso obuchwephesha bobuchwephesha. Kuyenzeka ukuba ugcine ngaphezulu kwe-20% yezinto eziluhlaza ezifana ne-PVC okanye i-PO.

Kuphela zii-scrims kuphela ukuvumela ukuveliswa kwemveliso ecekeceke kakhulu ye-membrane yokuphumla kwe-membrane (i-1.2 mm) edla ngokusetyenziswa kumbindi weYurophu. Iindwangu azinakusetyenziselwa umoya ovuthayo onqabileyo kune-1.5 mm.

Ubume besixhobo se-scrim asibonakali kancinci kwimveliso yokugqibela kunesakhiwo sezinto ezilukiweyo. Oku kuphumela kumhlaba oshukumayo kunye nemveliso yemveliso yokugqibela.

Umphezulu otyhafileyo weemveliso zokugqibela eziqulathe i-Scrims ivumela ukuba i-weld okanye ii-GLUE zeemveliso zokugqibela kwaye zinqula ngokuhlala.

Umphezulu ogudileyo uya kuxhathisa ukunyangwa ixesha elide nangakumbi.

Ukusetyenziswa kwe-glassfibre scrim kugxilwe ngaphandle kwe-nowlovens yezantya eziphezulu zomatshini wokuveliswa kwamaphepha ophahla lwe-bitu-amadoda. Ixesha kunye neenyembezi zabasebenzi abaziinyembezi kwizityalo zephepha le-bitumen ke zinokuthintelwa ke.

Amaxabiso omatshini ophahla lwamaphepha e-bittumes aphuculwe kakhulu ngamaqhinga.

Izixhobo ezidla ngokukrakra ngokulula, ezinje ngephepha, i-foil okanye iifilimu ezivela kwiplastiki ezahlukeneyo, ziya kuthintelwa ukuba zitshixe ngokuphumelelayo ngokunakalisa iziqwengana.

Ngelixa iimveliso ezilukiweyo zinokunikwa i-loomstate, i-scrim ifakwe i-skrim iyohlala ingenanto. Ngenxa yale nyaniso sinolwazi olunzulu malunga nalowo umbizi onokuthi ulunge kakhulu kwizicelo ezahlukeneyo. Ukukhetha iklinikhi elungileyo kunokuphucula ukonwaba kweSkrim kunye nemveliso yokugqibela.

Isibakala sokuba i-Warp ephezulu nezantsi kwi-scrims iya kuhlala ikwicala elinye le-Weft iqinisekisa ukuba i-Warp ye-Warp iya kuhlala iphantsi kwengxabano. Ngenxa yoko amagunya amanxuwa kwigumbi lakwa-Warp Like ngokukhawuleza. Ngenxa yesi siphumo, esenziwe ngesikram kudla ngokubonisa i-Elonglongetion eqinileyo. inkqubo yokomisa. Oku kukhokelela ekuqhubeni i-polyester kunye nezinye ii-thermoplastic zeyants eziya kuphucula iindlela ezilandele kakhulu ezenziwa ngumthengi.

Ukuba unemibuzo yazo zonke izinto eziqhelekileyo zenziwe i-Scrims kunye neemveliso ze-fiberglass, ezinje

I-Pontuster Skrim ene-pupih binder,

I-Pontuster Skrim nge-pvc binder,

I-Figberglass Skrim kunye ne-pupih binder,

I-Figberglass Skrim nge-pvc binder,

Wamkelekile ukunxibelelana nathi, ngalo naliphi na ixesha!

IXESHA LOKUQALA: FEB-17 ukuya ku-1722